Prototek Plastics

Precision plastic parts delivered in days

Certifications:

ISO 9001 | ISO 13485 | AS9100 | ITAR

Locations:

Westminster, CO | San Jose, CA | Rancho Cordova, CA | Blue Mounds, WI | Menomonie, WI | Allentown, PA | Contoocook, NH (HQ)

Why Prototek Plastics?

Prototek’s on-demand plastic manufacturing, 100% controlled in house, leverages a multitude of processes and materials. Complex, fully finished plastic parts in days.

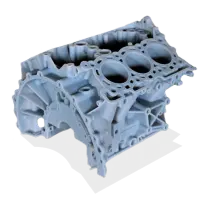

Capabilities

Prototek’s seven US facilities make it a one-stop shop for plastic prototyping and low-volume production. Using state-of-the-art additive and subtractive manufacturing, Prototek delivers high-precision parts and assemblies quickly and accurately. The result is fully finished parts in days.

Our plastic experts can provide design and manufacturing support, from prototyping to full-scale production. Using a variety of materials, Prototek can produce parts with complex geometries in a wide range of sizes and shapes. Complete post-processing services include finishing, painting, and assembly.

Prototek’s Additive Manufacturing processes include:

Laser Sintering: A high-powered laser fuses powdered thermoplastics to create complex geometric shapes with ease. Production parts are strong, heat-resistant, air-tight, water-tight, and can be dyed in various colors.

MultiJet Fusion: HP digital printing technology that uses powdered thermoplastics, a liquid agent, and infrared energy to fuse parts precisely. Advantages: speed, quality, cost, and open-source materials.

SLA - Stereolithography: UV-sensitive photopolymers cure instantly when activated by a laser. SLA offers dimensional accuracy and smooth surface finish in a variety of materials. Finished parts can be sanded, painted, dyed, electroplated, and machined.

DLP - Digital Light Processing: UV-sensitive liquid resin cured by a digital light projector. High-resolution parts with engineering-grade mechanical properties from rigid and elastomeric materials. Biocompatible and sterilizable, the parts have lattices and textures.

Hybrid PhotoSynthesis: UV-sensitive liquid resin cured by a digital light projector that offers clear material options and good repeatability. Advantages: Larger build surface compared to DLP, faster than SLA, and open-source material system.

Fused Filament Fabrication: Thermoplastic filament melted through a heated nozzle and selectively extruded, building layer upon layer to create durable parts. Advantages: High heat materials, dissolvable supports, a variety of production materials.

Material Jetting: UV-sensitive gel deposited by a printhead and immediately cured by a lamp. Unique ability to blend materials and colors. Advantages: High-quality prints, snap fits, and a variety of materials including medical grade and multi-durometer

Prototek’s other plastic manufacturing processes include:

Silicone/Urethane Casting: Production plastic parts without the wait. The silicone or urethane casting process creates a mold from a 3D-printed master pattern. The mold is used to form parts from liquid resin materials. The cast resin solidifies into end-use pieces with exceptional precision, consistency, and speed — making this manufacturing process ideal for low to medium-volume production runs (from 1 to 100s). Parts can be cast in a variety of polymers, including silicone and flexible or rigid urethanes.

Plastic Machining: CNC milling, routing, and turning across a range of plastic materials. Plastic machining can be a cost-effective way to enable precision and accuracy for complex shapes and parts. Benefits: high-quality surface finishing, intricate designs, and fast turnaround times.

Prototek’s innovative finishing techniques deliver beautiful end-use parts that are rugged enough to withstand real-world impacts. Finishing options include:

Automated Post-Processing

Bead Blasting, Sanding, and Priming

Painting, Clear Coating, and Dyeing

Soft Touch Finishes

Plating and EMI Shielding

Hardware Inserts

Full Assembly

Need quick-turn metal parts? See Prototek’s metal prototyping options.

Prototek offers over a hundred plastic materials, including:

Nylon, ABS, Thermoplastics, Polyurethane, Polycarbonate, Ultem, proprietary and specialty materials for 3D printing processes

Plastic Machined Materials:

ABS, Acrylic, Acetal, HDPE, Nylon, PEEK, Polycarbonate, Polypropylene, Radel, and Ultem

Material characteristics are nearly unlimited:

Solid or multi-color, clear, flexible, rigid, durable, impact resistant, UV stable, biocompatible, medical grade, heat resistant, chemical resistant, flame retardant, and more

Prototek’s online Material Pro platform helps you compare additive materials based on your part’s unique requirements. This extensive resource offers detailed material characteristics and technical data sheets.

.png)